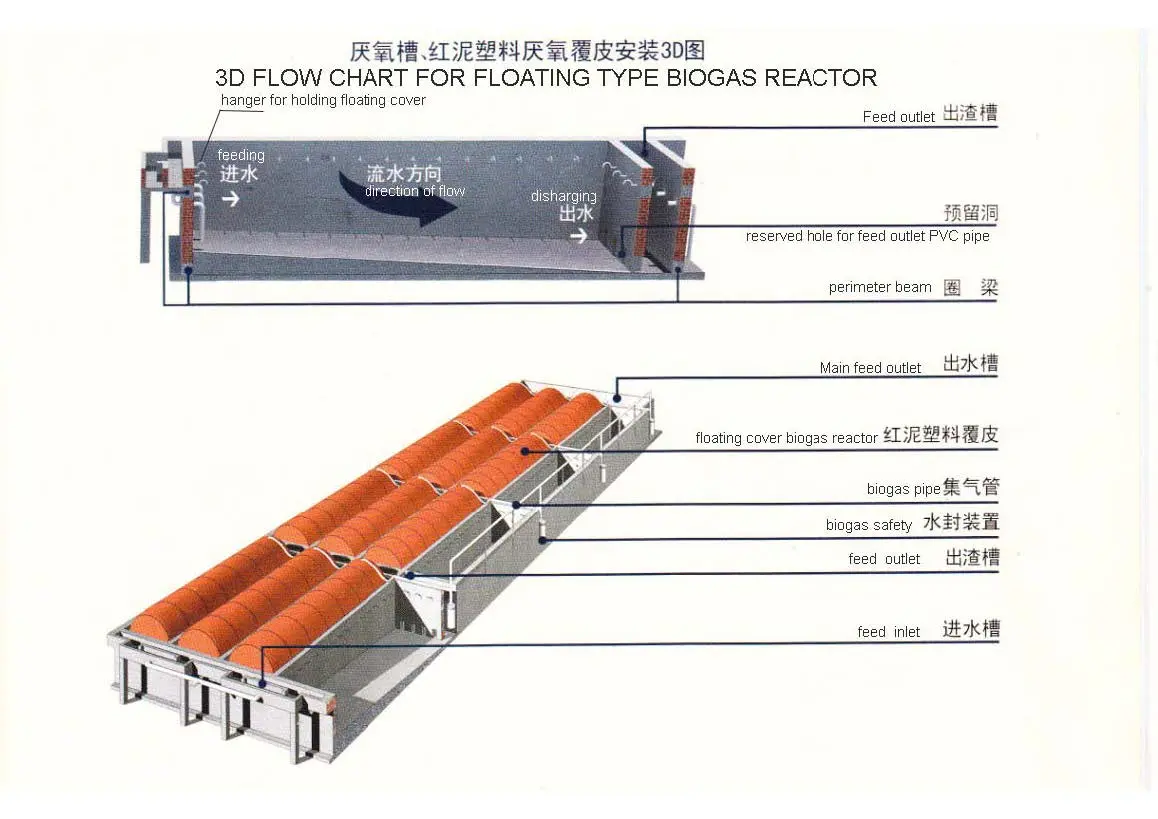

Floating Cover Biogas System

The square floating biogas system uses a square floating Cover made of high-strength red mud PVC film material as a soft gas collection hood installed on a rectangular biogas tank. It is mainly used for 100-2000 cubic meters of biogas projects. It is easy to install, foldable, low transportation cost, and low maintenance and operation cost.

The maximum volume of its single unit can reach 100 cubic meters. For biogas projects larger than 100 cubic meters, multiple biogas tanks are operated in parallel. This design can effectively reduce the organic load rate of the entire biogas tank, so that the internal biogas raw materials can be fully decomposed and the gas production can be increased. It is especially suitable for warm climates such as Africa and Southeast Asia, and is more economical than enamel biogas projects.

Merit and demerit of the floating cover type biogas digester

A. merit

The bogas digester is of good performance in bearing capacity, and makes full use of the bearing capacity of earth. Thus, it can save both time and material.

It can use various kinds of raw materials as the fermenting materials, such as straw.

It can build under the toilet and pigsty so that the dung can goes into the biogas digester automatically.

B. The advantages compared with other biogas digester

It can fix the mix to eradicate incrustation to increase the output of biogas.

It also solves the problems of gas leakage, difficult feeding and discharge and maintenance.

It is much cheaper than the glass fiber reinforced plastic biogas digester. And it is light, collapsible, easy to install and transport, low cost in maintenance

C. Demerit

The invariably pressure during 1.5—6kpa will do harm to the intensity of biogas digester and the use stability of biogas appliances.

DIY system

All the fittings we will provided for you with users’ manual.Biogas digeter,biogas pipe fittings,solar biogas pump(optional),biogas stove,biogas safety valve,biogas water separator will be in pacakage.Only needs several hours to install the biogas system.

Change waste to energy

A Polythene Biogas unit can yield a whole range of benefits for their users, the society and the environment in general, the chief benefits being;

1. Production of energy (heat, light, electricity).

2. Transformation of organic wastes into high quality fertilizer.

3. Improvement of hygienic conditions through reduction of pathogens, worm eggs and flies.

4. Reduction of workload, mainly for women, in firewood collection and cooking.

5. Environmental advantages through protection of forests, soil, water and air.

6. Global Environmental Benefits of Biogas Technology.

The calorific value of biogas is about 6 kWh/m3 – this corresponds to about half a litre of diesel oil. The net calorific value depends on the efficiency of the burners or appliances. Methane is the valuable component under the aspect of using biogas as a fuel.

Biogas use, replacing conventional fuels like kerosene or firewood, allows for the conservation of environment. It therefore, increases its own value by the value of i.e. forest saved or planted.

Biogas is able to substitute almost the complete consumption of firewood in rural households.

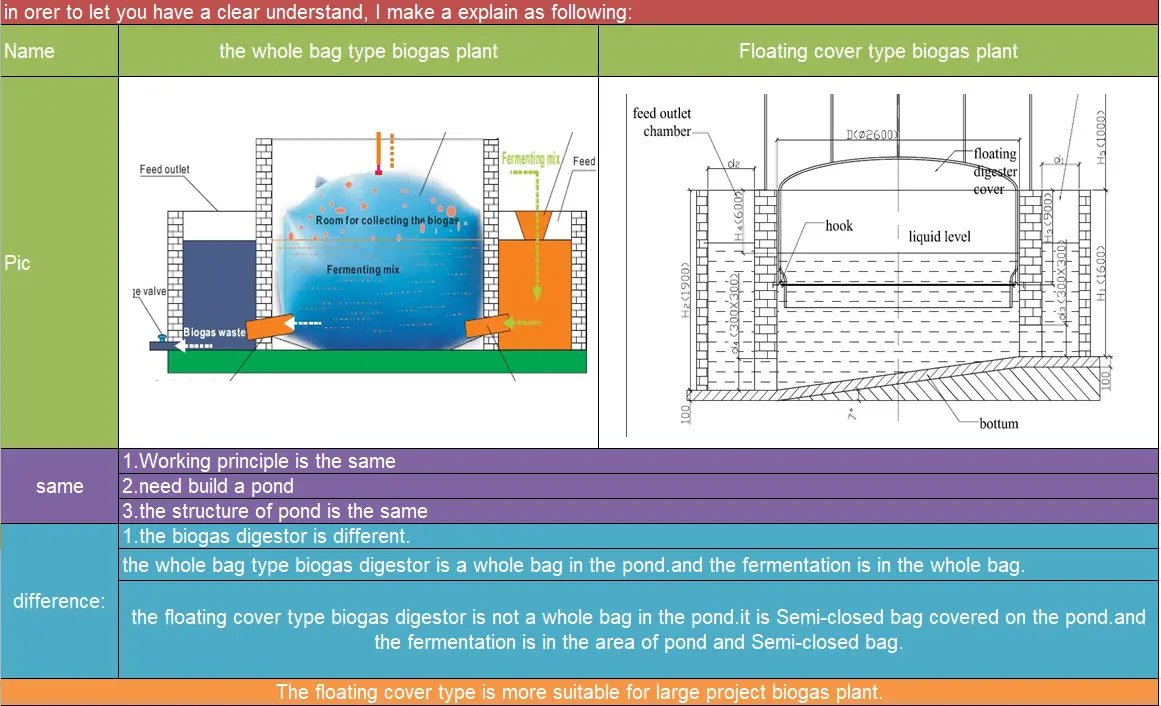

Different between the whole bag type biogas plant and Floating cover type biogas plant

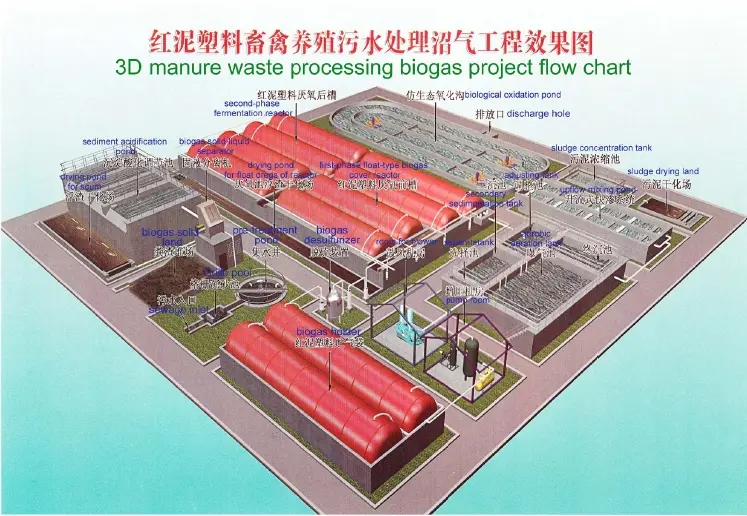

3D flowchart of floacting cover biogas system

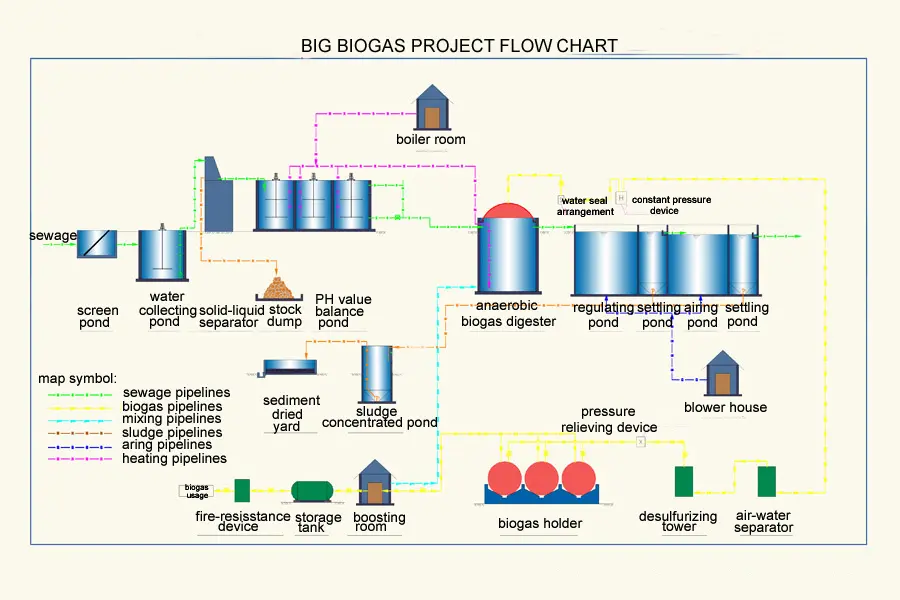

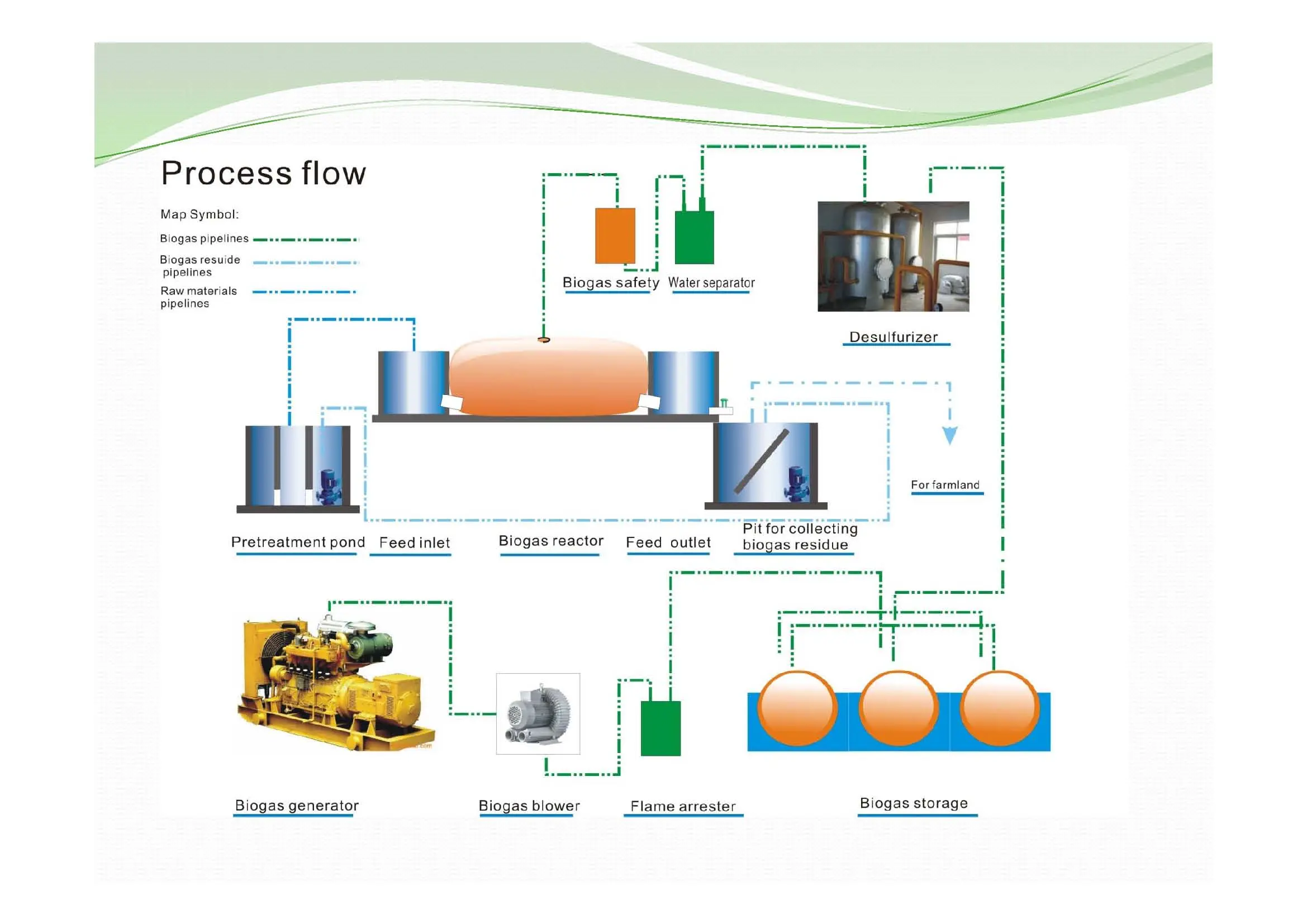

HOW IS THE BIOGAS DIGESTER OPERATING?!

1.The fermenting mix(manure,sewage,some other waste mix etc.) enters into the feed inlet by the conical inlet orifice.

2.The fermenting mix will enter into the biogas reactor by the feed pipe automatically.

3.All the fermenting mix will stay in the biogas reactor on the condition of anaerobic to ferment. The various organic microorganisms will produce biogas . Because the biogas’ water insoluble, it will go up to the room which is for collecting biogas from bottom of reactor in the form of bubbles . (Therefore, the air tightness of the biogas reactor is very important.)

4.After about 7—15 days, the whole process of producing biogas completed. The remaining matters are biogas liquid and biogas solid, which is called biogas waste. It will enter into feed outlet by the feed outlet pipe.

5.Open the discharge valve,the biogas waste will flow out of feed outlet automatically.

6.Some of biogas liquid can be reused to ferment again. The other will be good organic fertilizer for plants .

7.The biogas will enter into the biogas-guide tube.

8.Biogas safety equipment: Its main function is to release some biogas to ease pressure of the biogas when the pressure is too big.Therefore,people won’t worry explosion of reactor.

9.Air-water separator:It gets rid of the water in the biogas.

10.Biogas devulcanizer:It gets rid of the H2S in the biogas.

11.Biogas pump: It pressurizes the biogas when its pressure is low. It can assure that the biogas appliances run constantly and stably.

12.Biogas storage bag: It holds the biogas . 1.The fermenting mix(manure,sewage,some other waste mix etc.) enters into the feed inlet by the conical inlet orifice.

2.The fermenting mix will enter into the biogas reactor by the feed pipe automatically.

3.All the fermenting mix will stay in the biogas reactor on the condition of anaerobic to ferment. The various organic microorganisms will produce biogas . Because the biogas’ water insoluble, it will go up to the room which is for collecting biogas from bottom of reactor in the form of bubbles . (Therefore, the air tightness of the biogas reactor is very important.)

4.After about 7—15 days, the whole process of producing biogas completed. The remaining matters are biogas liquid and biogas solid, which is called biogas waste. It will enter into feed outlet by the feed outlet pipe.

5.Open the discharge valve,the biogas waste will flow out of feed outlet automatically.

6.Some of biogas liquid can be reused to ferment again. The other will be good organic fertilizer for plants .

7.The biogas will enter into the biogas-guide tube.

8.Biogas safety equipment: Its main function is to release some biogas to ease pressure of the biogas when the pressure is too big.Therefor,people won’t worry explosion of reactor.

9.Air-water separator:It gets rid of the water in the biogas.

10.Biogas devulcanizer:It gets rid of the H2S in the biogas.

11.Biogas pump: It pressurizes the biogas when its pressure is low. It can assure that the biogas appliances run constantly and stably.

12.Biogas storage bag: It holds the biogas .