Continuous Improvement is Our Commitment.

wangliyuan factory

We customize the design according to your needs and the geographical environment where the product is used and installed. We strive for perfection in every detail from size to material.

Visit Our Factory

Processing Inspections Exceed Industry Standard

In controlling the quality of each stage within every production, we have process inspections to improve production efficiency.

Checking Raw Material

Our technicians conduct thorough inspections of the appearance, size, color, customer specifications and performance of incoming materials.

Cutting Raw Material

The raw sheets are cut with our laser.Laser cutting uses a high-power laser which is directed through optics and computer numerical control (CNC) to direct the beam or material. Typically, the process uses a motion control system to follow a CNC or G-code of the pattern that is to be cut onto the material.

Deburring &Electrostatic spray painting.

Deburring of sheet metal is the removal of irregularities and sharp edges on metal products.Electrostatic spraying is a coating method that uses a spray gun to positively charge electric particles while the workpiece is grounded, or negatively charged.

Brushing - Bending

Amet minim mollit non deserunt ullamco est sit aliqua dolor do amet sint. Velit officia consequat duis enim velit mollit. Exercitation veniam cons equat sunt nostrud met. Amet minim mollit non deser ullamco est.

Powder

The POESTA process combines the powder with the raw sheets through an electrostatic process.

Enamel

The powder and the raw sheet combine in our high-performance furnace at approx. 800°C, creating an absolutely corrosion-resistant surface.

Inspection

After the furnace, the panel are subjected to a comprehensive pore inspection and a detailed visual inspection by our qualified employees.

Packing

Before the panels are packed, an edge protection is applied as a transport protection. Ready-packed, the panel packages are commissioned for specific projects.

Flexible Tank for Liquid &Gas

Cutting Raw Material

The selected materials will be hand-cut according to the cutting drawings designed by engineers to ensure that every detail is in place.

Welding 01

Small containers are usually heat sealed only on hot air heat sealers, which are quick and convenient and can fit the material well, especially for long or curved heat seal lines..

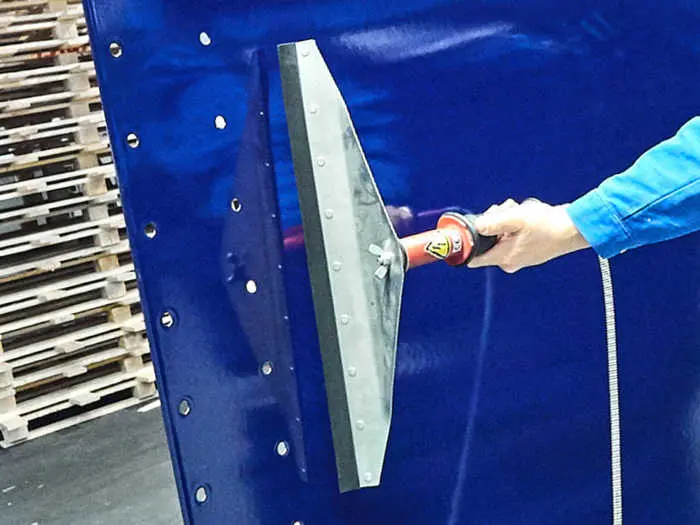

Welding 02

There are many types of PVC containers. Some plastic flanges, air nozzles or some special heat seals need to be combined with customized molds on this high-frequency heat sealer to be perfectly heat-sealed and very firm and durable..

Welding 03

This large heat sealing machine is specially used for producing double film air storage bags. The material of this type of air storage bag is very thick and requires high-strength heat sealing to ensure a complete fit..

Get In Touch Now!

Get A Quote Today To Receive Your Custom Design Within 7 Working Days!

WLY is the world’s largest manufacturer of factory-coated storage tanks and biogas project system for municipal and industrial water and wastewater applications.